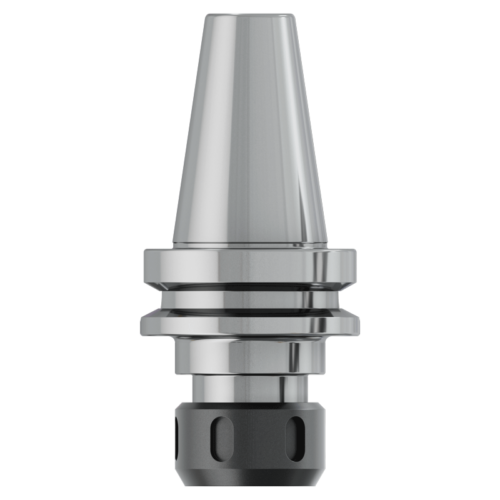

Holding Systems (rotating tools) in CNC machining are integral components designed to securely hold and align cutting tools for precise and efficient machining operations. These systems encompass a variety of holder types, each tailored to specific machining requirements and tool types.

The Holding System for rotating tools is crucial for achieving precision in CNC machining. It encompasses a range of tool holders, including hydraulic, shrink-fit, and collet chuck systems, each designed to provide optimal tool stability and alignment for various machining processes.

Key Features and Benefits:

Precision Alignment: Ensures accurate tool positioning, leading to high-quality machining results and reduced tool wear.

Versatile Application: Suitable for a wide range of machining operations, from high-speed milling to precision drilling and tapping.

Enhanced Tool Life: By providing a stable and secure hold, these systems reduce vibrations and tool deflection, extending tool life.

Quick Change Capabilities: Many holding systems allow for rapid tool changes, minimizing downtime and increasing productivity.

Material Compatibility: Designed to accommodate tools for machining a variety of materials, from soft plastics to hardened steels.

Applications and Purposes:

Utilized in diverse machining environments, including automotive, aerospace, and metal fabrication industries.

Ideal for tasks that demand high precision and stability, ensuring consistent performance across various machining applications.

The Holding System for rotating tools is a cornerstone of efficient and accurate CNC machining, offering the flexibility and reliability required to meet the demanding standards of modern manufacturing processes.