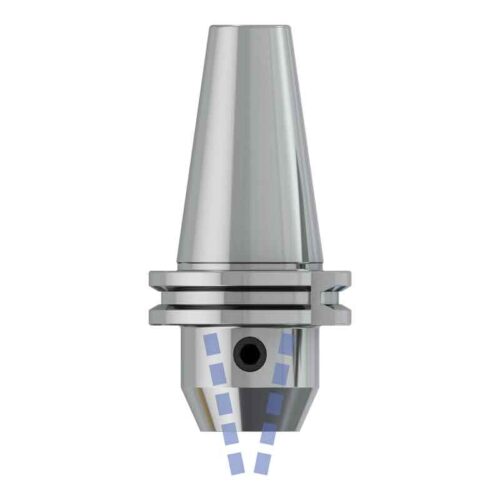

SK Tool Holders for rotating tools are designed for use in CNC machining centers, providing a secure and precise connection for various cutting tools. These holders follow the SK (Steilkegel) standard, known for its steep taper design, which ensures high accuracy and rigidity in tool clamping and performance.

SK Tool Holders (Rotating Tools) are integral components in CNC machining, offering enhanced precision and stability for high-speed operations. Adhering to the Steilkegel (SK) standard, these tool holders feature a steep taper design that ensures a tight and accurate fit between the spindle and the tool, maximizing performance and productivity.

Detailed Features and Benefits:

Steep Taper Design: The SK tool holders’ characteristic steep taper provides excellent concentricity and rigidity, reducing vibration and improving machining accuracy.

High-Speed Machining: Engineered for high-speed applications, these holders maintain stability and precision under the demanding conditions of high rotational speeds.

Durability and Reliability: Made from high-quality materials, SK Tool Holders withstand the stresses of continuous use, ensuring long-term reliability and performance.

Versatile Tool Compatibility: Compatible with a wide array of rotating tools, such as drills, mills, and taps, allowing for flexibility in machining processes.

Efficient Tool Changes: The design facilitates quick and easy tool changes, minimizing downtime and enhancing overall productivity.

Applications and Purposes:

Predominantly used in precision machining sectors like automotive, aerospace, and engineering, where high-speed and accuracy are paramount.

Ideal for operations that require meticulous control and stability, such as complex milling, precision drilling, and high-speed tapping.

SK Tool Holders (Rotating Tools) provide a reliable and efficient solution for high-speed CNC machining, ensuring optimal performance, accuracy, and stability in demanding machining environments.