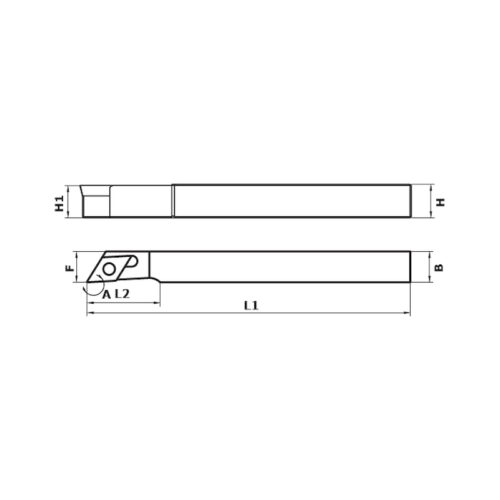

External Turning Tool Holders are made for CNC turning operations, designed to secure cutting tools for external machining tasks. These holders come in various styles and configurations to accommodate different cutting needs and machining conditions.

External Turning Tool Holders are integral to CNC lathes, facilitating precise and efficient external machining. They are designed to accommodate a wide range of cutting tools, ensuring versatility and adaptability in various machining environments. These tool holders are crafted for durability and performance, providing a stable and accurate cutting action.

Advantages:

Precision and Quality: Ensure accurate and consistent machining, producing high-quality surface finishes and precise dimensions.

Durability and Strength: Constructed from premium materials, these holders withstand demanding machining conditions and extend tool life.

Versatility and Customization: With a range of holder types, they can be tailored to specific machining needs, offering flexibility in tool selection and application.

Cost-Effective: Reduce downtime and operational costs by enabling quick tool changes and efficient machining strategies.

By offering a comprehensive range of External Turning Tool Holders, manufacturers can meet the diverse needs of modern machining operations, ensuring precision, efficiency, and versatility in external turning processes.

Varieties:

External Indexable

External Threading Indexable

External Grooving & Parting

External Face Grooving