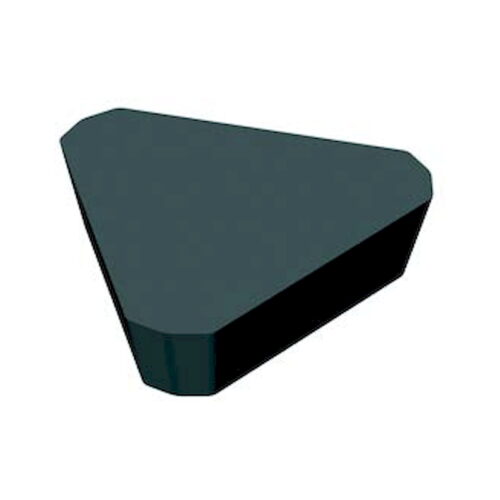

Carbide Inserts are replaceable used in machining steels, cast iron, high temperature alloys, and nonferrous materials. They offer superior wear resistance and precision cutting.

Carbide Inserts are essential components in modern machining, offering unmatched durability and cutting precision. These inserts are made from tungsten carbide, an extremely hard material that maintains a sharp cutting edge at high temperatures, significantly extending tool life.

Key Features and Benefits:

Exceptional Hardness: Provides excellent wear resistance and longevity, even in high-speed applications.

Precision Cutting: Delivers clean and accurate cuts, enhancing the quality of the machined surface.

Versatility: Available in various geometries and coatings to suit a wide range of materials and machining operations.

Efficiency: Easy to index or replace without removing the toolholder, minimizing downtime.

Applications and Purposes:

Broadly utilized in CNC machining, turning, and milling operations across automotive, aerospace, and metal fabrication industries.

Ideal for precision work on hard and abrasive materials where tool wear is a significant concern.