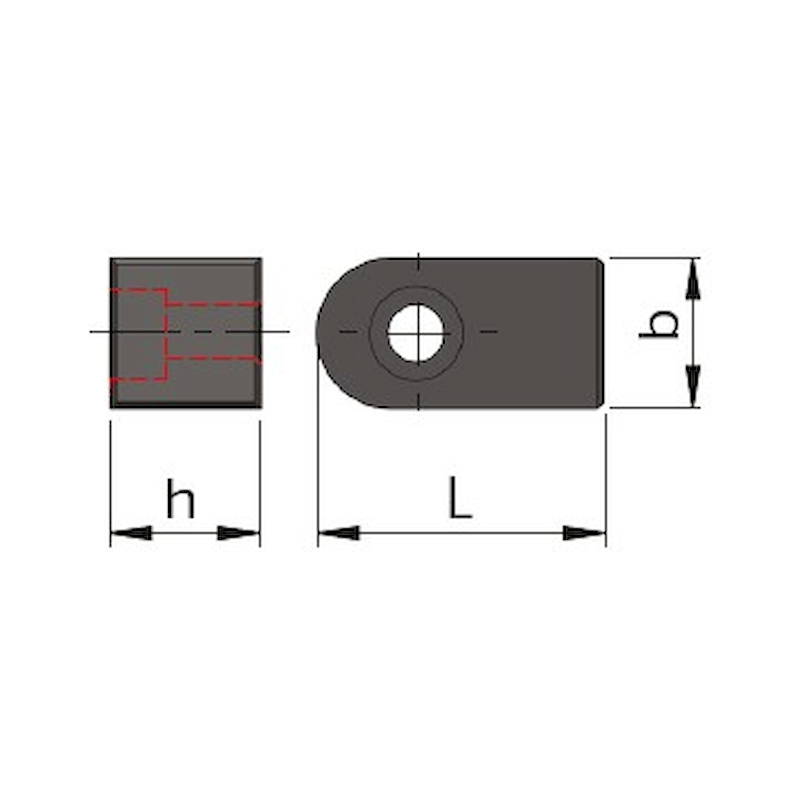

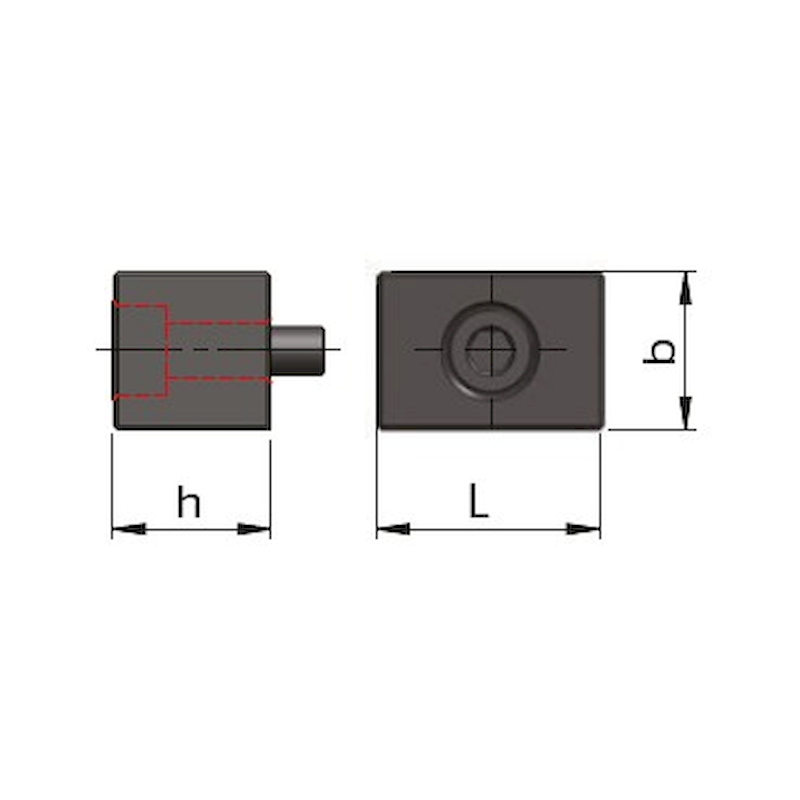

| Item Code | Product Name | b | h | L | FIG |

| HEI.Z.MS.Q316.17 | Q 16 QUERNUT | 8 | 9 | 17 | FIG1 |

| HEI.Z.MS.Q322.17 | Q 22 QUERNUT | 10 | 10 | 17 | FIG1 |

| HEI.Z.MS.Q327.23 | Q 27 QUERNUT | 12 | 12 | 23 | FIG1 |

| HEI.Z.MS.Q332.27 | Q 32 QUERNUT | 14 | 15 | 27 | FIG1 |

| HEI.Z.MS.Q340.28 | Q 40 QUERNUT | 16 | 16 | 28 | FIG1 |

| HEI.Z.MS.Q327.14 | Q 27 QUERNUT | 12 | 12 | 14 | FIG2 |

| HEI.Z.MS.Q332.22 | Q 32 QUERNUT | 14 | 14 | 22 | FIG2 |

| HEI.Z.MS.Q340.23 | Q 40 QUERNUT | 16 | 16 | 23 | FIG2 |

“Driving Blocks for Shell Mill Holders” are mechanical components that ensure the secure attachment and precise alignment of shell mill holders on the milling machine spindle. These blocks engage with specific slots on the shell mill holder, transferring the rotational force from the spindle to the holder and preventing any slippage during operation. Key Features and Benefits: Secure Engagement: Provides a robust connection between the shell mill holder and the spindle, enhancing the transfer of rotational force. Precision Alignment: Facilitates accurate positioning of the shell mill holder, ensuring consistent and effective milling. High Durability: Constructed from materials capable of withstanding the high torque and stress of milling operations. Compatibility: Designed to fit various types of shell mill holders, accommodating a wide range of milling applications. Applications:Primarily used in CNC milling to secure shell mill holders for operations such as face milling, slotting, and shoulder milling. Suitable for industries requiring high precision and reliability in their milling processes, like aerospace, automotive, and general manufacturing. Driving Blocks for Shell Mill Holders are essential for maintaining the stability and efficiency of milling operations, ensuring that the shell mill holder performs optimally under varying machining conditions.